Description

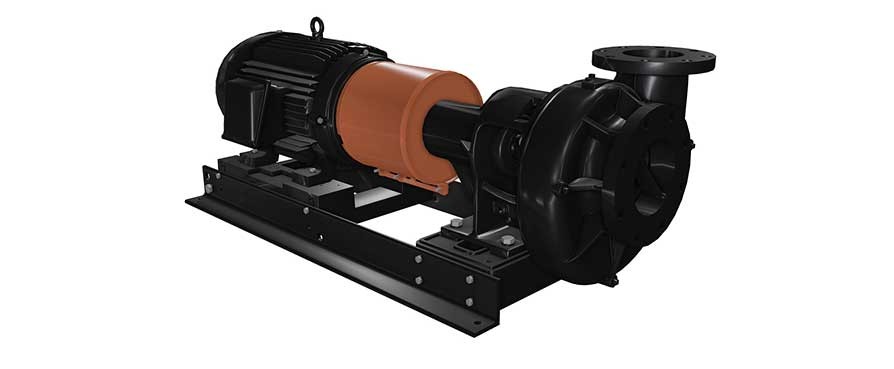

Overview

Grundfos mixers and flowmakers provide energy efficient mixing. The drive unit is equipped with IE3 motor components, and combined with the large variety of gear steps, this enables Grundfos to provide a suitable mixer or flowmaker within the overall range. Additionally, a variable speed drive can be added for even better performance adaption. Mixers and flowmakers ensure that particles remain evenly distributed in wastewater and sludge, preventing sedimentation and supporting treatment processes.

The range covers everything from small-scale mixers, ideal for prefabricated pumping stations, to large-scale flowmakers designed for large tanks and basins. Wastewater infrastructure is an obvious application area – from network stations to treatment plants – but the mixing power of the SMD, SMG, and SFG ranges is also appreciated by industry and agriculture professionals worldwide.

Applications

The mixers and flowmakers are designed for mixing, i.e. homogenization and suspension, of liquids in:

- > municipal wastewater treatment systems

- > sludge treatment systems

- > sewage pumping stations

- > wastewater treatment plants

- > industrial processes

- > agriculture

- > bio gas plants

The mixers and flowmakers are fitted with stainless steel or polyurethane propellers with diameters between 160 and 2660 mm and rotation speeds between 25 min-1 and 1500 min-1(50 Hz).

Features and benefits

- > Highly energy-efficient products, driven by IE3 motor components

- > wide range of flexible installation accessories

- > simple maintenance and service electronic

- > leak sensor and moisture switch

- > shaft seal protected against abrasive materials

- > self-cleaning stainless steel or polyurethane propellers

- > hydraulically efficient and robust propellers

- > stainless steel or cast-iron motor housing